TOKYO--(BUSINESS WIRE)--NIPPON KINZOKU CO., LTD. (TOKYO: 5491) (Headquarters: Minato-ku, Tokyo) have realized welded and drawn tubes "Fine Pipe" with excellent quality above seamless pipes by using particularly selected materials by us as a material manufacturer. We provide the products with excellent quality at low cost by applying our own process (welding-drawing-annealing) and the latest specially designed facilities.

Features

-

Eco products

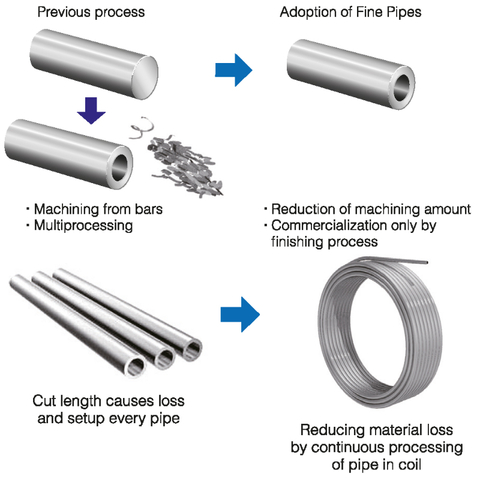

By switching from seamless pipes, the cutting process can be omitted which can save resources and reduce costs significantly. -

Integrated manufacturing from materials

We select the optimum material based on customers’ specifications. -

Pressure resistance and durability surpassing seamless pipes

Due to less uneven thickness and unique welding technology, it has pressure resistance and durability that surpass that of seamless pipes. -

High precision and low cost

Fine pipes made with high precision materials and proprietary pipe-forming technology are more precise than welded pipes and less expensive than seamless pipes. -

Selectable product forms

The product is available in the form most convenient for the customer such as coil-wound, standard-length, pre-cut to length and special processing.

Steel grades and Available sizes

https://www.nipponkinzoku.co.jp/assets/images/2023/12/Steel-grades-and-Available-sizes.png

Application examples

-

Automotive parts

Fine pipes are high-quality and extremely reliable, and therefore have a key role in automotive components such as fuel pipes and sensor components. Additionally, they meet wide range specification such as Thick-walled tube for high pressure (OD: less than 20mm, thickness: Maximum 2.0mm), Heat-resistant alloys for high-temperature applications (SUS310S, Inconel601 etc.) based on long-time know-how as the materials manufacture. -

Measurement and industrial equipment

Fine pipes with high-precision finishing in terms of internal surface roughness, circularity and straightness, and made to optimum quality for each application, are adopted in a various fields as key parts. -

Analysis equipment

Special processing is also available in addition to common pipes. Secondary operations such as sealing the end of small diameter and long pipes, machining, pressing and drawing, which are not possible with drawing, as well as long coiling of multiplexed and internally filled pipes are also available.

About NIPPON KINZOKU Group

Our products have been used in a range of areas from the precision field to the construction industry. https://www.nipponkinzoku.co.jp/en/