SHANGHAI--(BUSINESS WIRE)--Henkel has established a brand new processing and testing line in Shanghai (P.R. China) to focus on Electro Ceramic Coating (EC²) technology in Asia-Pacific. This laboratory will serve customers who are interested in using EC² to replace traditional coating methods for corrosion protection, as well as customers who require the new high performance benefits of reduced friction and reduced emissions in internal combustion engines. Located in Henkel’s Asia-Pacific R&D center in Shanghai, this 100-square-meter lab, equipped with world-class infrastructures and led by an experienced technical team, will develop and test electro ceramic coatings tailored to the customer’s requirements.

Henkel already has three EC² laboratories around the world, located in Detroit (United States), Düsseldorf (Germany) and Yokohama (Japan). The new lab in Shanghai now makes it possible to quickly tailor the coating process based on the specific requirements of local customers in China and Asia Pacific. Performance and analytical characteristics can also be tested on site in the well-equipped Henkel Analytical Center.

What is EC²?

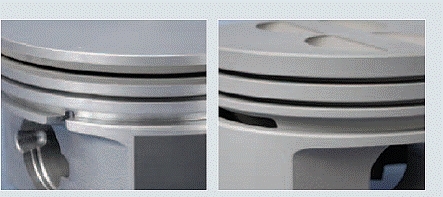

EC² is a high-performance, environmentally-friendly, multifunctional coating for light metals such as aluminum, magnesium, titanium and their alloys. The coating enables the use of lower-cost and lightweight metals, for example, to replace steel. Test results have verified that EC²can provide enhanced heat and chemical resistance, as well as superior corrosion protection. EC² can also be used as a base coating with an excellent adhesion to paints.

New high-performance benefits of EC² include the reduction of friction and improvement of wear characteristics, and the reduction of emissions in internal combustion engines.

Applications of this technology include: marine outboard engines, automotive engine pistons, exhaust gas recirculation and turbo parts, HVAC, pistons for small engines, pumps and valves, cookware, lighting, and many more components across industries.

Significance

The new EC² processing and testing lab will allow Henkel to develop more lightweight and environmentally-friendly solutions to help customers reach their targets of emission reduction and fuel efficiency. It will not only reinforce Henkel’s Asia-Pacific technical capability, but also proactively support the innovation process at the customer end. Besides, it can bring extra value to the customers by enabling Henkel to respond more rapidly to their requirements. “Henkel has always committed to be the design partner and solution provider of our customers. We are excited to strengthen this commitment by providing our latest innovative coating technology,” said George Kazantzis, Vice President of Henkel Asia-Pacific Transportation and Metals Group.

About Henkel

Henkel operates worldwide with leading brands and technologies in three business areas:

Laundry & Home Care, Beauty Care and Adhesive Technologies. Founded in 1876, Henkel holds globally leading market positions both in the consumer and industrial businesses with well-known brands such as Persil, Schwarzkopf and Loctite. Henkel employs about 47,000 people and reported sales of 16,510 million euros and adjusted operating profit of 2,335 million euros in fiscal 2012. Henkel’s preferred shares are listed in the German stock index DAX.