OSAKA, Japan--(BUSINESS WIRE)--At the latest major of the marine coatings market, the main type of antifouling paint is hydrolysis, and it exerts antifouling performance by dissolving hydrolysis resin and biocide into the ocean.

Under that situation, it has a possibility to be affected to dissolve hydrolysis resin and biocide excessively into the ocean by external factors, for instance, due to rising sea temperatures or ship speed etc. To resolve these issues, Nippon Paint Marine focused on the structure of the coating surface of the antifouling paint and strove to create “Hydrophilic & Hydrophobic Nano domain structures”.

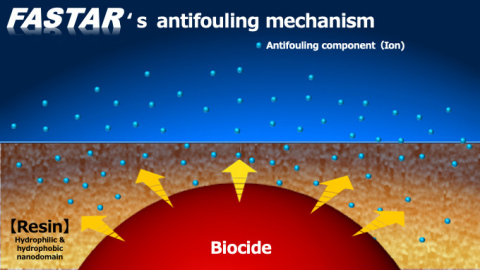

“Hydrophilic & Hydrophobic Nano domain structures” has achieved a truly effective paint to set proper dry film thickness and it exerts excellent antifouling performance. It is made possible adding new mechanism to conventional technology to more precisely control the release of hydrolysis resin and antifouling ion into the ocean.

The nano domain structure is formed of both hydrophilic & hydrophobic domains laid out in molecular patterns and it enables antifouling diffusion and retention from the antifouling agent "biocide", and it shows excellent antifouling performance.

This product, already applied in trial to 10 vessels in 2020, has been launched in January 2021. It secured approximately 60 ships in 2021 improving the marine environment on an ESG perspective and saving a fuel consumption more effectively.

FASTAR realizes 7-8% fuel energy saving just by A/F

FASTAR XI and FASTAR XII incorporate pioneering water trapping hydrogel technology used in A-LF-Sea system as “biomimetic technology” that shows fuel saving effect, and the percentage of the fuel saving is to be about 7-8% in A/F only compared with current SPC AF. The application of dry dock will be greatly improved by coating drying time and procedure.

Especially during the winter, there is a possibility that the application process can be shortened approximately 37%. Also, it is possible to anchor for up to 45 days in seawater temperature of below 25°C.