TOKYO--(BUSINESS WIRE)--Mitsui Chemicals Inc. (TOKYO:4183)(President & CEO: Tsutomu Tannowa) announced that the Group’s unique metal resin integral technology, POLYMETACTM has been selected for use in the frames of new autonomous unmanned aerial vehicles which are currently being developed by Aerosense Inc. (Tokyo; CEO: Hisashi Taniguchi), a joint venture of Sony Mobile Communications Inc. and ZMP Inc.

POLYMETACTM is Mitsui Chemicals’ completely new technology for strong adhesion and bonding of various metals and resins that was not possible using conventional methods.

Out of Mitsui Chemicals’ numerous lightweight solutions, POLYMETACTM cuts weight and helps to reduce the number of parts and steps in the manufacturing processes as well. It is a completely new technology that provides totally new hybrid solutions.

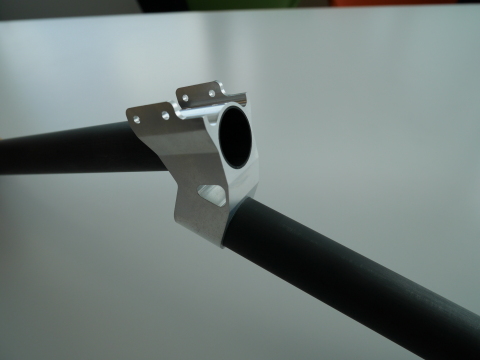

Mitsui Chemicals provides Aerosense with hybrid product of carbon fiber reinforced plastic (CFRP) and aluminum joint parts made by its POLYMETACTM technology and provides full support in shaping and designing the parts which will be used in the frame of aerial vehicle.

The new joint parts greatly enhance the structural rigidity of aerial vehicles while significantly reducing weight and providing simpler designs by eliminating the need for fasteners such as bolts.

“Our autonomous unmanned aerial vehicles provide solutions to various industrial needs. It is important that we are able to provide greater flight distances and improved performance by reducing weight and the number of parts while ensuring durability and strength of our aerial vehicles,” says Hisashi Taniguchi, CEO of Aerosense. “Mitsui Chemicals’ POLYMETACTM technology makes it possible to extend flight distance by 40% providing our customers with greater added value.”

“POLYMETACTM allows adhesion and bonding of various metals and resins, and for the current project, CFRP and aluminum parts were integrated by its technology,” says Akio Hirahara, General Manager of Mitsui Chemicals’ New Market Development (Automotive Materials) Division. “Mitsui Chemicals used its cutting edge simulation technology to design simple joint shapes with a single part which were originally composed of approximately 20 pieces. The technology contributes to a 50% weight reduction of joint parts while improving rigidity.”

Mitsui Chemicals will continue to pursue new uses and development of POLYMETACTM technology for state-of-the-art lightweight solutions in automotive and electrical applications.

About Mitsui Chemicals (Tokyo: 4183, ISIN: JP3888300005)

Mitsui Chemicals’ roots can be traced back to 1912 when it began producing raw material for chemical fertilizers from coal gas byproducts, the first company in Japan to do so. This undertaking significantly contributed to increasing agricultural productivity, a major social issue at the time. Later, the company evolved its technology from coal chemicals to gas chemicals, and in 1958 it built Japan’s first petrochemical complex and so provided impetus to Japan’s industrial sector. Today, the company boasts many world-class products with sales standing at 1,550 billion yen and with over 135 companies in 27 countries. Its business portfolio includes environment-friendly materials for next-generation mobility, healthcare services to realize health and happiness in an ageing society, packaging that ensures the reliability and safety of food products, agrochemicals that contribute to increased production of food, electronic materials, and environment-friendly materials for the energy sector.

Mitsui Chemicals will continue to contribute to solving social challenges with its state-of-the-art technology and by "Creating New Customer Value through Innovation".

More information can be found at http://www.mitsuichem.com/index.htm

|

Outline of Aerosense Inc. |

||

| Company name | Aerosense Inc. | |

| Head office | 5-41-10 Koishikawa, Bunkyo-ku, Tokyo, Japan | |

| Establishment | August 2015 | |

|

Stated capital |

100 million yen |

|

|

Capital reserve |

100 million yen |

|

| Investment ratio |

Sony Mobile Communications Inc. : 50.005% |

|

| Business | Development, manufacture, and sale of industrial solutions using autonomous unmanned aerial vehicles for image capture combined with cloud-based data processing. | |